Rectangular busbar series with double tire insulation

Usage

Closed rectangular conductor with copper busbars in solid epoxy insulation is designed to

perform electrical connections in AC circuits of 6 (10) kV at facilities requiring additional insulation

of copper busbars. For example, from aggressive air environment at metallurgical and

petrochemical plants.

TU 3414-011-73361303-2007.

Technical Specifications

|

Title |

Value |

|

Rated voltage, kV |

6, 10 |

|

Maximum voltage, kV |

12 |

|

Rated current, A |

1600 |

|

Maximum current, A |

1900 |

|

Thermal resistance current, kA / 3 sec |

25 |

|

Electrodynamic resistance current, kA |

63 |

|

Test voltage, kV / 1 min |

42 |

|

Test impulse voltage, kV |

75 |

|

Rated frequency, Hz |

50, 60 |

|

Permissible temperature of the current lead during operation, ° C - for live parts - for metal housing |

90 50 |

|

Type of cooling |

Natural |

|

Installation height above sea level, m |

To 1000 |

|

Climatic modification, category of accommodation |

UHL 3.1 (*NF) |

DESIGN

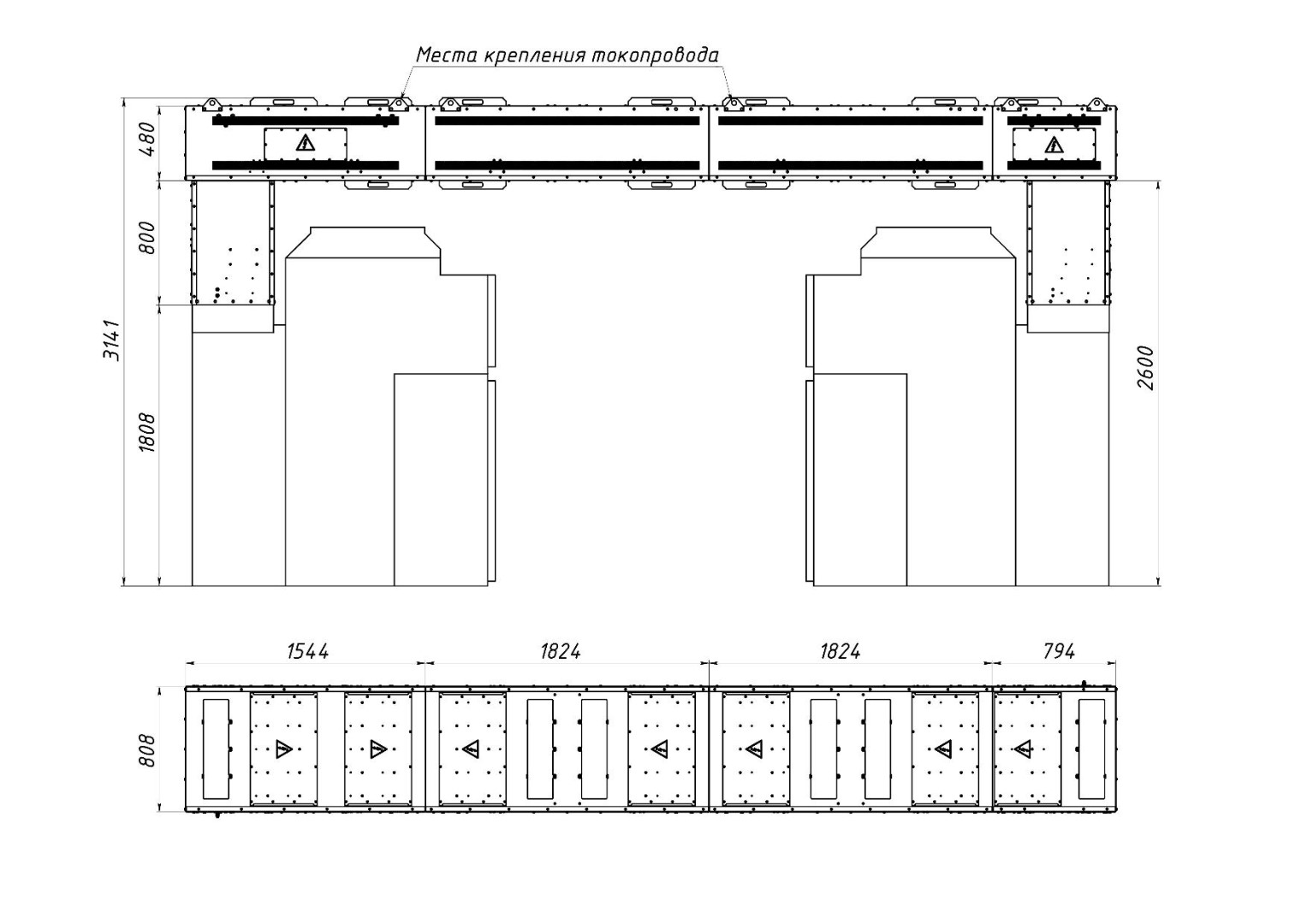

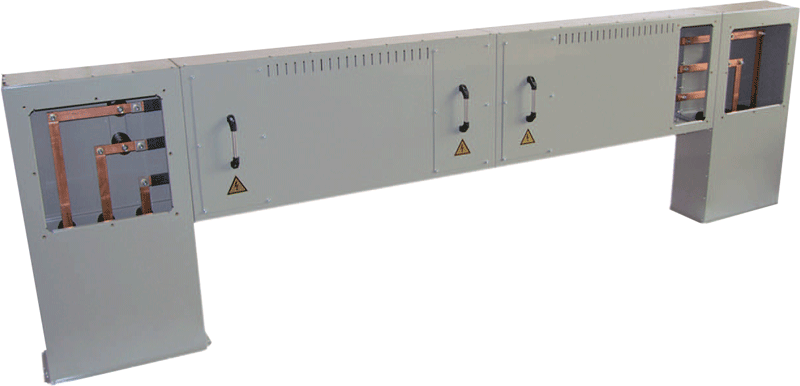

The busbar consists of rectilinear and angular sections and is a three-phase system of insulated current-carrying buses mounted on epoxy supports. Corner sections are connected to the switchgear cells, single-end service assembly chamber. The section panels are made of 2 mm sheet steel coated with epoxy-polyester powder paint, color RAL 7035. An example of a sectional busbar attached in Appendix A.

The busbars are epoxy insulated with fins for better cooling and a better creepage distance. The tires are made of solid copper with a full profile of 80 × 10 mm.

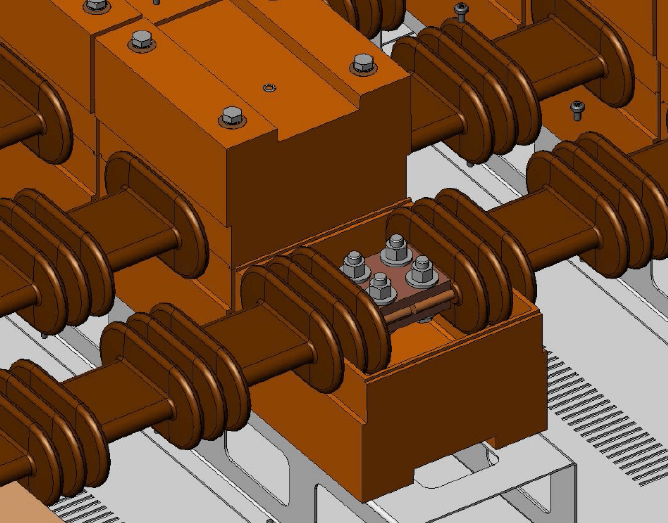

Tires are connected through copper plates using disc washers providing a fixed force. The busbar junctions are covered with epoxy boxes.

DESIGN FEATURES

- tire insulation is made of an epoxy compound by injection molding, with preliminary evacuation, and has high electrical characteristics;

- dust and moisture resistance of epoxy insulation, self-extinguishing property;

- impossibility of short circuit between tires;

- corrosion resistance of copper tires to aggressive environments;

- touch security;

- high manufacturing accuracy allows installation at the facility without presence of manufacturer.

ADDITIONAL INFORMATION

Busbar includes:

- hatches for mounting copper busbars;

- pressure relief valves;

- places for slinging sections.

All set includes lubricant EPS-98 TU 2257-001-47926093-99 to reduce contact resistance. It is possible to supply additional equipment according to agreement with the customer. For example, arc protection devices, voltage indication devices, etc.

The busbar complies with requirements for cast current conductors. The dimensions are slightly larger than a molded busbar, but much cheaper in terms of price and operating costs. The design is much more convenient for connecting to switchgear cabinets compared to regular molded busbars.